PLASTIC ADDITIVES(樹脂添加劑)

We control the properties of diverse plastic materials to enrich everyday life.

Plastic materials are vulnerable to deterioration and discoloration due to heat, light, and oxygen exposure.

Plastic additives can control and suppress defects in the production process caused by various deterioration.

In recent years, there is a growing awareness of environmental needs, and environmentally-friendly products are receiving greater attention.

One example is a worldwide demand to reduce toxic heavy metals which impact the environment.

Our company is proud to offer a wide range of alternative products with low environmental impact and excellent processibility, such as calcium/zinc-based composite stabilizers.

PRODUCT LIST

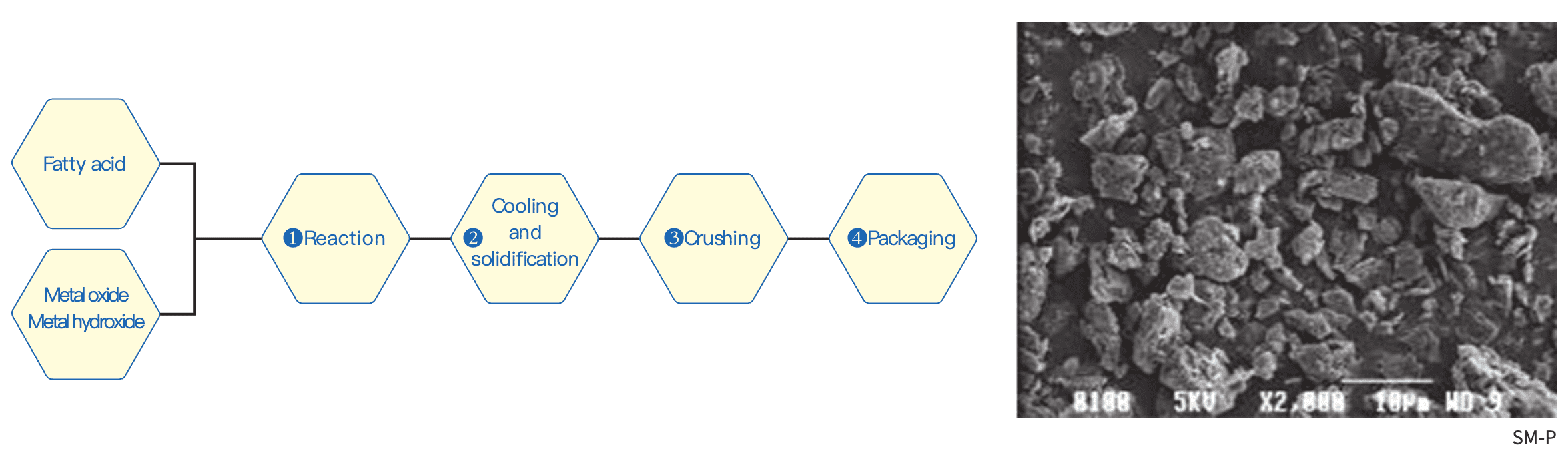

- Metallic Soap

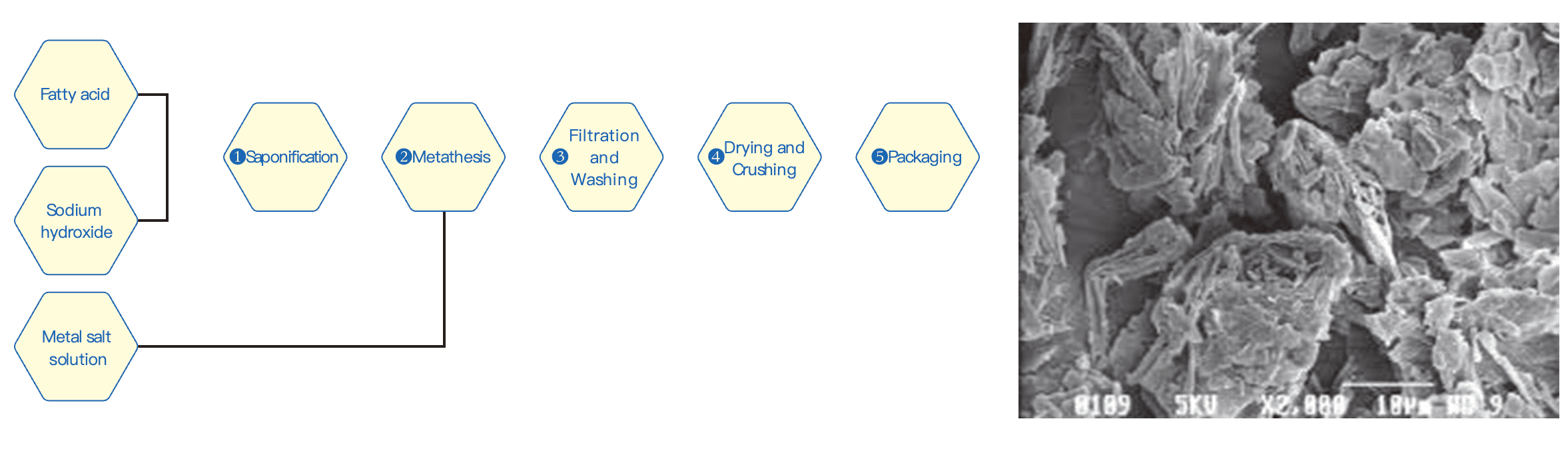

- Hydrotalcite

- Flame Retardants